GibbsCAM 2026 26.0.46.0: The Advanced Solution for CNC Programming & Manufacturing Excellence 🖥️✨

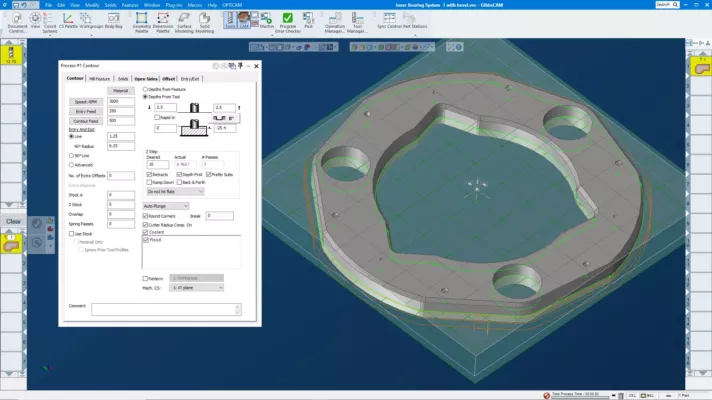

In the competitive world of manufacturing and machining, efficiency, precision, and speed are paramount. GibbsCAM 2026 26.0.46.0 is a powerful Computer-Aided Manufacturing (CAM) software designed to simplify CNC programming, optimize toolpaths, and increase productivity for mills, lathes, and multi-axis machines.

Whether you’re a job shop, a manufacturing engineer, or a machinist, GibbsCAM provides the tools and intelligence to turn designs into precise, high-quality parts efficiently.

🎯 Why Choose GibbsCAM 2026?

- ✅ Intelligent Machining Strategies: Automate toolpath creation for speed and efficiency

- ✅ Comprehensive Machine Support: From simple 2-axis mills to complex multi-axis machines

- ✅ Advanced Toolpath Control: Fine-tune cutting parameters for optimal results

- ✅ Integrated Simulation & Verification: Check for collisions and errors before machining

- ✅ Robust Post-Processing: Generate reliable, machine-specific G-code

- ✅ Focus on Speed & Simplicity: Reduces programming time significantly

Perfect for CNC programmers, machinists, manufacturing engineers, and job shops.

✨ Key Features of Version 2026.0.46.0

🧰 1. Flexible & Intelligent Toolpathing

- 2.5D & 3D Milling: Face, pocket, contour, drill, and more

- Turning & Multi-Task Machining: For lathes and mill-turn centers

- 5-Axis Machining: Advanced strategies for complex geometries

- Feature Recognition: Automatically identify and program standard features

- Adaptive Clearing: Optimizes tool engagement for faster, safer roughing

🖥️ 2. Intuitive Programming Environment

- Associative Toolpaths: Toolpaths update automatically when geometry changes

- Visual Programming: See your toolpath develop in real-time

- Flexible Workflows: Program parts based on features, operations, or tooling

🔍 3. Simulation & Verification

- Solid Material Removal Simulation: Visualize the finished part

- Collision Detection: Check for tool, holder, and machine collisions

- Force Modeling: Predict and optimize cutting forces

- G-Code Verification: Ensure code matches intended toolpath

🧩 4. Post-Processing & Integration

- Extensive Post-Processor Library: Supports thousands of machine controls

- Custom Post Development: Create or modify post-processors in-house

- Seamless CAD Integration: Import data from major CAD systems (STEP, IGES, Parasolid, etc.)

- Shop Documentation: Generate operation sheets and tool lists

🛠️ Ideal For:

- CNC Programmers: Creating efficient, reliable G-code

- Machinists: Understanding and verifying machining operations

- Manufacturing Engineers: Optimizing production processes

- Job Shops: Handling diverse parts and tight deadlines

- Anyone: Requiring powerful, flexible CAM software

💡 Tip: Use the Adaptive Clearing strategy to significantly reduce roughing time on milled parts.

🆚 GibbsCAM vs. Other CAM Software

GibbsCAM is known for its intelligent, feature-based programming and strong post-processing.

💡 Final Thoughts: Program Smarter, Machine Faster

GibbsCAM 2026 26.0.46.0 empowers manufacturers to achieve greater efficiency and precision in their CNC operations. By combining intelligent toolpathing, powerful simulation, and reliable post-processing, it helps you produce better parts, faster.

🏭 Program. Simulate. Manufacture. Excel.

🌐 Official website: https://gibbscam.com (Note: Verify exact product page for GibbsCAM 2026 26.0.46.0)

💻 Compatible with Windows.

✔ Tested: This software was tested on Windows 10 & Windows 11 and works smoothly without issues.

Frequently Asked Questions

- Is this software free?

Yes, it can be downloaded and used for free. - Does it support Windows 11?

Yes, it works perfectly on Windows 10 and 11. - Is it safe to use?

Yes, the software was scanned and tested before publishing.

Last updated: January 2026